Back

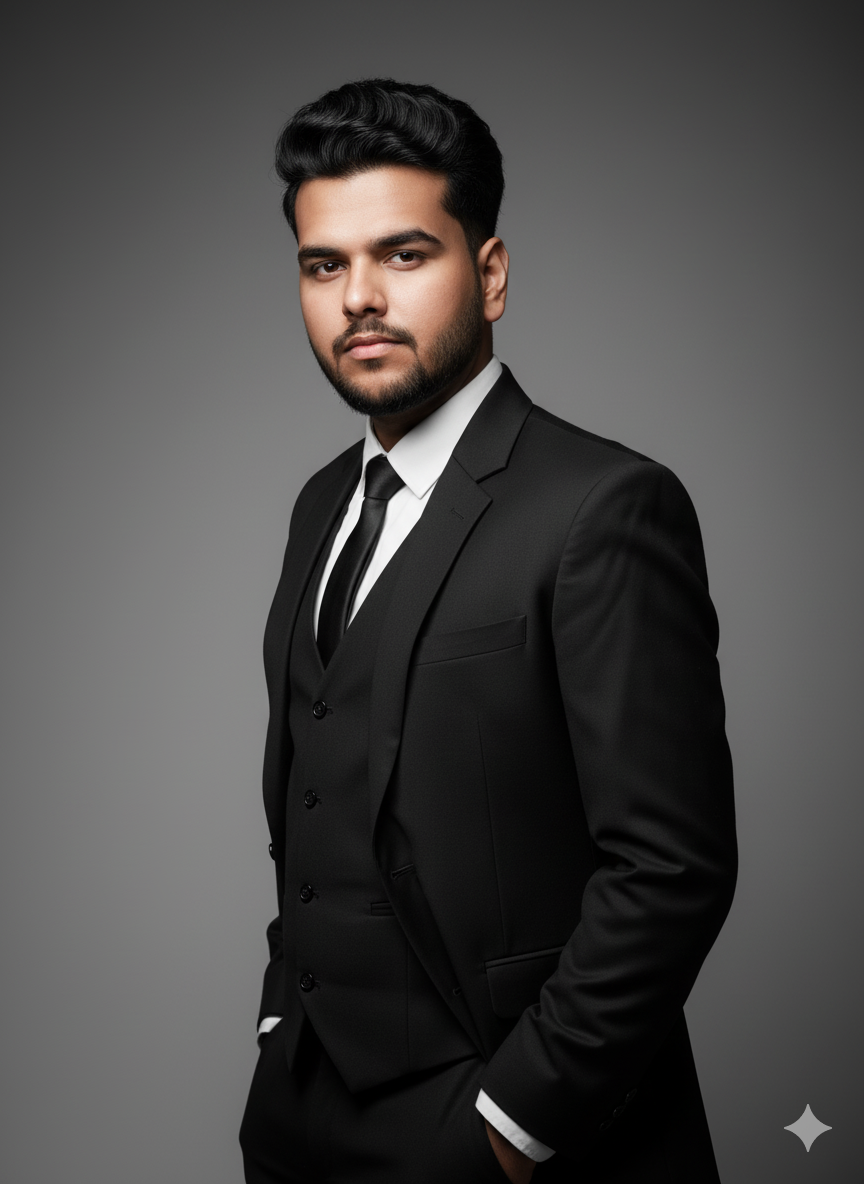

Saurabh Singhavi

Assisting Early-Stag... • 11m

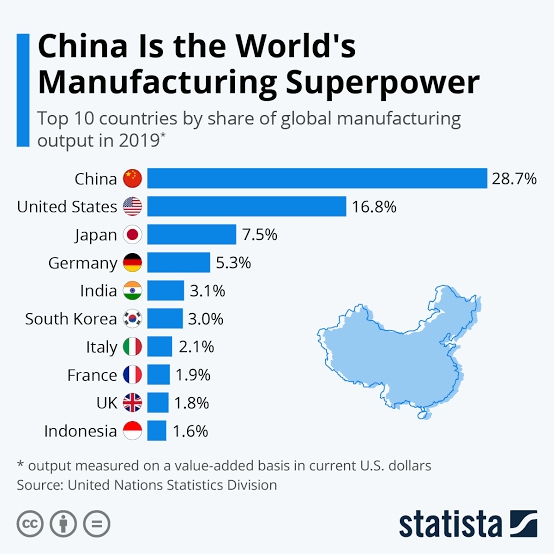

Why Are Only 3% of Indian Factories Using AI While China Surges to 25%? Let’s Break It Down. The Stark Reality: - 3% vs. 25%: Just 3% of Indian factories use AI vs. 25% in China (NITI Aayog, 2023). - Productivity Lag: Indian factories operate at 60% capacity vs. China’s 85% (World Bank). - Cost of Delay: Inefficient manufacturing costs India ₹1.2 lakh crore annually in wasted resources (McKinsey). Why the Gap? 1. MSME Challenges: 95% of Indian factories are small-scale—struggling with upfront costs and tech literacy. 2. Skill Shortage: India trains 40K AI professionals/year; China trains 500K. 3. Infrastructure Hurdles: Only 25% of factories have reliable IoT connectivity vs. China’s 80%. 4. Policy Push: China invests $3B/year in AI for manufacturing; India allocates $100M. The Opportunity: - $15B Market: India’s AI sector is growing at 33% CAGR (NASSCOM). - Affordable Solutions: AI-as-a-service models are slashing costs (e.g., predictive maintenance tools for ₹15K/month). - Global Lessons: Brazil boosted SME productivity by 20% via AI subsidies—can India replicate this? Entrepreneurs: Are you doing anything about it? hashtag#AI hashtag#MakeInIndia hashtag#FutureOfWork hashtag#Innovation hashtag#Manufacturing

Replies (4)

More like this

Recommendations from Medial

Himanshu Dodani

Start now what you j... • 10m

No one can beat China, even the US. Here's why: 1. Production Cost: iPhone assembly in China costs ~$6/unit vs. $30+ in the US. Tesla builds EVs in Shanghai 30% cheaper than in the US. 2. Labor & Scale: Average manufacturing wage in China is ~$3.5

See More

Jainil Prajapati

Turning dreams into ... • 10m

🚨 INDIA VS CHINA IN DEEP TECH: WHY ARE WE LAGGING? 🤔 China’s startups are CRUSHING IT in AI, semiconductors, EVs, and battery tech. Meanwhile, India’s focus? Food delivery & fantasy sports. 😑 In 2024, China’s AI/semiconductor VC funding hit $12.3

See MoreSunderam Dutta

Best your best. • 1y

A twitter user shared the fact that a 9 kw LED bulb manufactured in China costs 15 to 25 rs and a ln Alibaba supplier is ready to ship it for 35 rs to India, I did the fact and it wright. The manufacturing gap between India and China is huge, it cost

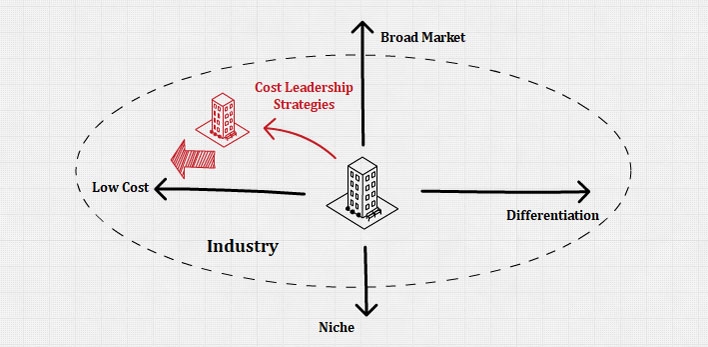

See MoreSHIV DIXIT

CHAIRMAN - BITEX IND... • 1y

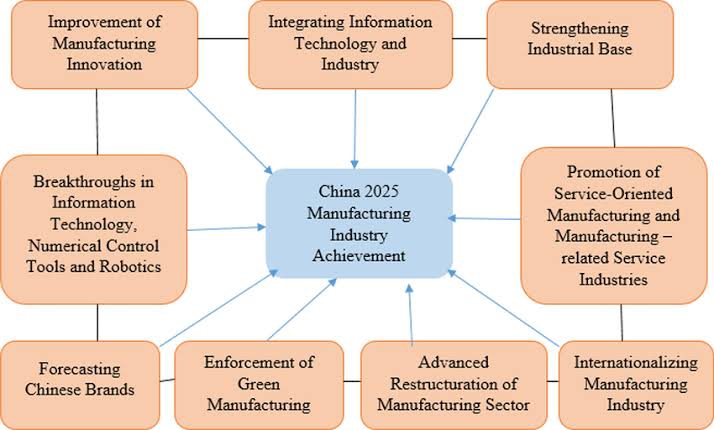

“China Manufacturing strategy breakdown” Do you know China is Earning whole India gdp with the help of manufacturing. Basically China is entrepreneur economy and around 29% global manufacturing belongs to china worth ( 4 Trillion dollars ). Chin

See More

VCGuy

Believe me, it’s not... • 10m

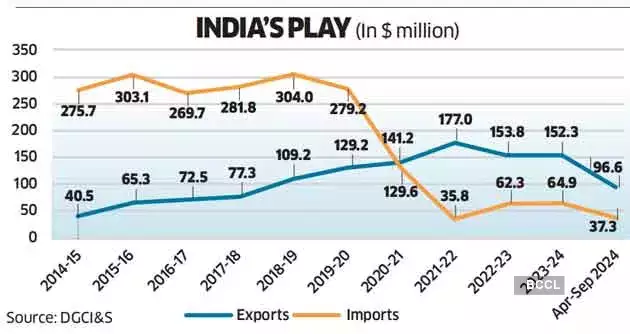

India's toy industry will likely emerge as a winner through Trump Trade Tariffs. At present - majority of the world's toys are manufactured and supplied by China and Vietnam. China facing over 54% and Vietnam's 46% tariffs, Indian Toy manufacture

See More

VCGuy

Believe me, it’s not... • 10m

India's toy industry will likely emerge as a winner through Trump Trade Tariffs. At present - majority of the world's toys are manufactured and supplied by China and Vietnam. China facing over 54% and Vietnam's 46% tariffs, Indian Toy manufacture

See More

SamCtrlPlusAltMan

•

OpenAI • 1y

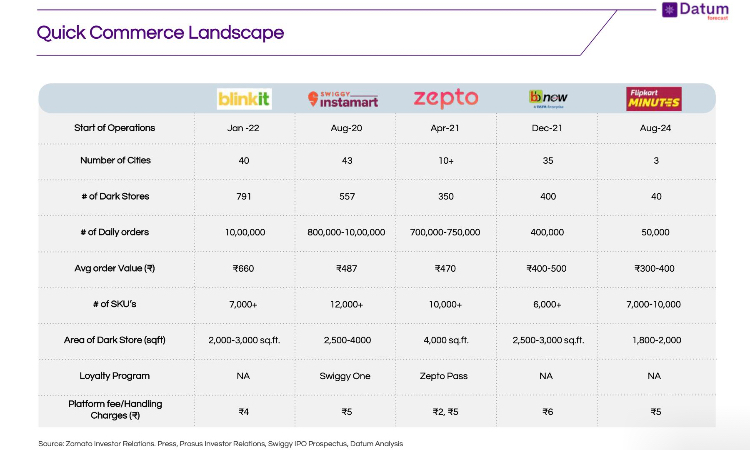

Quick Commerce Battle: David vs Goliaths? Flipkart Minutes enters quick commerce as the newest player - but here's why size might not matter: While Blinkit processes 10L daily orders vs Flipkart's 50K... And has 791 dark stores vs Flipkart's 40...

See More

Download the medial app to read full posts, comements and news.

/entrackr/media/post_attachments/wp-content/uploads/2021/08/Accel-1.jpg)